DN1 Durable tension meter for high tensions

Durable tension meters for a wide range of applications in the textile, fiber and wire industries.

Durable tension meters for a wide range of applications in the textile, fiber and wire industries.

The DN1 analog tension meter shows changing and fluctuating tensions fast, it enables an optimal process adjustment .The built-in material thickness compensator compensates different material diameters for a particular range (only DN1-1000 and higher ranges). The scale (54 mm Ø) is easy to read, the linearized scale provides a clear reading. The filament guide and roller shifting mechanism ensure easy acquisition of the running material.

Features

- Large, easy to read scale (54 mm Ø)

- Shock-resistant movement

- Filament guide and roller shifting mechanism ensure easy acquisition of the running material

- Ball-bearing mounted, V-grooved guide rollers

- Special calibration is available

- Specific Test Report with calibration test report optionally available

- Linearized scale provides a better reading

- Built-in material thickness compensator improves accuracy for changing diameters on DN1-1000 and higher ranges

- Everything in operator's view:

- the guide rollers

- the measured material

- the readings - Each instrument is individually calibrated for highest accuracy

- Rugged aluminum housing

Tension meter with carrying case, operating instructions in English or German as requested

Note: Models DN1-30K and DN1-50K are delivered with roller R12013 as default

| Model | Ranges | Measuring Head Width* mm | SCHMIDT Calibration Material** | MTC** | ||

| DN1-120 | 20-120 | 65 | PA: 0.12 mm Ø | |||

| DN1-200 | 20-200 | 65 | PA: 0.12 mm Ø | |||

| DN1-400 | 20-400 | 65 | PA: 0.20 mm Ø | |||

| DN1-1000 | 50-1000 | 65 | PA: 0.30 mm Ø | |||

| DN1-2000 | 200-2000 | 116 | PA: 0.50 mm Ø | |||

| DN1-3500 | 400-3500 | 116 | PA: 0.80 mm Ø | |||

| DN1-5000 | 400-5000 | 116 | PA: 0.80 mm Ø | |||

| DN1-8000 | 500-8000 | 116 | PA: 1.00 mm Ø | |||

| DN1-10K | 2-10 daN | 116 | PA: 1.00 mm Ø | |||

| DN1-20K-L | 5-20 daN | 216 | PA: 1.50 mm Ø | |||

| DN1-30K-L | 5-30 daN | 265 | PA: 1.50 mm Ø | |||

| DN1-50K-L | 5-50 daN | 265 | Steel rope: 1.50 mm Ø (7x7x0.20) | |||

| Other tension ranges and measuring head widths available on request. Other units of measure available - g or kg. * Depending on model, either width of filament guide or outer distance between outside guide rollers ** Suitable for 95% of applications - PA = Polyamide Monofilament ***MTC = Material Thickness Compensator Special calibration using customer supplied samples is recommended, if process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape. For this purpose a material sample of about 5 m should be supplied. | ||||||

| Code | Roller material | Line Speed | |

|---|---|---|---|

| Code: Standard | Hardcoated aluminium | 2000 |

|

| R12013 | Plasma-coated aluminium Standard for Models DN1-30K-L and DN1-50K-L only | 1000 |

|

| K | Hardcoated aluminium | 3500 |

|

| H | Plasma-coated aluminium | 5000 |

|

| T | Plastic (POM) black | 1000 |

|

| W | Nickel-plated steel | 1000 |

|

| ST | Hardened steel | 1000 |

|

| B | Tempered steel for tire cord | 1000 |

|

| CE | Ceramic | 1000 |

|

| ASY | Hardcoated aluminium , asymmetrical groove | 1000 |

|

| U | Hardcoated aluminium (Radius R3) | 2000 |

|

| Code A: Air Damping | Code L: Special Lever |

|---|---|

This adjustable mechanical air dashpot is recommended for applications in which great fluctuations of the measured tension occur, as in spooling and winding machines. | Facilitates acquisition of the running material when measuring high tensions. |

|  |

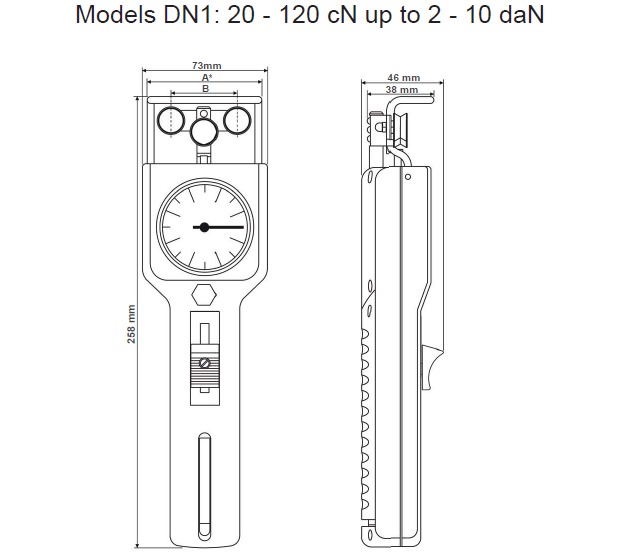

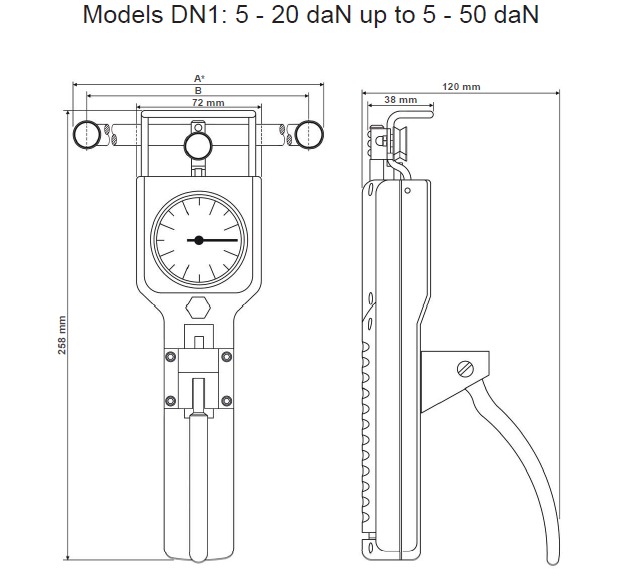

Dimensions

Specifications

| Calibration: | According to SCHMIDT factory procedure |

| Accuracy: | ±1% full scale (FS) or ±1 graduation on scale |

| Scale diameter: | 54 mm |

| Temperature range: | 10-45ºC |

| Air humidity: | 85% RH, max. |

| Housing material: | Die-cast aluminum |

| Housing dimensions: | 220 x 74 x 42 mm (L x W x H) |

| Weight, net (gross): | up to DN1-10K approx. 700 g (1200 g) DN1-20K-L and higher ranges (approx.) 900 g (2200 g) |