Time 3200/3202 Surface Roughness Tester

Designed as a multi-purpose surface roughness tester the TIME 3200/3202 is a versatile piece of equipment that can perform with high accuracy.

The TIME 3200/3202 comes as a complete kit but and can be extended for specific tasks like measuring in a deep groove, a small hole or in hard to reach places that have no room to position the complete device.

It is suitable for the more demanding test tasks due to its extensive range of functions. In addition to the basic functions, the device enables testing of many critical applications.

An inductive transducer with a diamond tip performs the physical measurements. Voltages are generated when the sensor is deflected, they are then converted into a roughness pattern by the instrument's electronic system.

The measured surface profiles can be presented on the display in addition to the different characteristics.

With a large spectrum of roughness measurement parameters, 13 for the 3200 and 17 for the TIME 3202, virtually every type of surface roughness measurement can be made using this device.

The TIME 3200/3202 surface roughness tester comes standard with a protective cover for the pickup and a steel support that is mounted to the back of the device. This enables the operator to elevate and level out the device when measuring above the plain surface. Plus there are several optional add-ons that enable specific measuring positions like a leveling table and a measuring platform.

The kit comes with a RS232 communication cable that can connect the TIME 3200/3202 with an optional printer or a PC that runs the software for TIME 3200/3202 surface roughness testers, or you can use the up to 15 groups data and graph internal storage that can be transferred at a later date, including all the measurement characteristics and surface profile.

The TIME 3200/3202 Surface Roughness Tester is designed for practical use in the workshop as well as for universal measurement tasks in the laboratory.

Features

- High performance instrument

- Graphical display on large LCD

- Pick-up stylus position indicator

- Data output RS-232 to printer TA-220 or PC

- Excellent battery power with Li-ion technology

- Easy to operate menu software

- 13 different roughness parameters

- Auto-off after 5 minutes, with auto-store

- Selectable language English, German, French, Italian, Spanish and Dutch

The TIME3200/3202 Surface Roughness Tester is delivered as a complete kit including:

- Detector TS-100

- Roughness test plate Ra

- Protection nose

- Steel support for rear leveling and stabilizing

- Charger 220V, 50Hz

- Screwdriver

- Carrying case

- Manual

- Certificate

Optional accessories:

- Special detector for Curved surface TS-110

- Special detector for small holes TS-120

- Special detector for deep grooves TS-130

- Special detector right angled pickup TS-140

- Extension TSE-A

- Extension TSE-B 90°

- UKAS certified reference standards

- TA-610 test platform

- Steel adapter (ø 8mm)

- Steel adapter for connection to platform TA-610 (L-attachment)

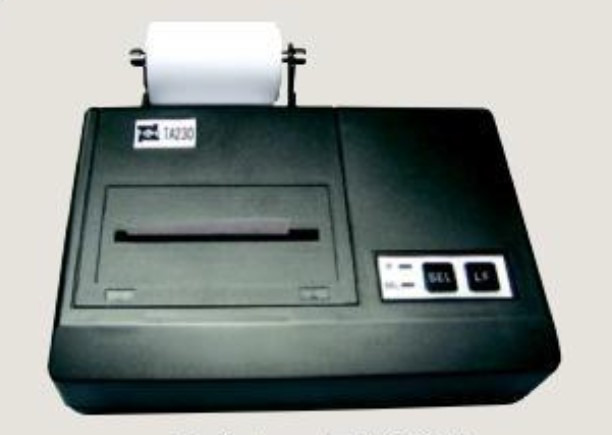

- TA-230 printer

Surface roughness measurement,

Surface roughness is a variation in the material surface on a microscopic scale, it determines the visual effect of a surface, shiny or mat, and the friction of the material vs another surface sliding over it.

In a lot of cases the roughness determines the characteristics of the material or object. Things like the ability to form a seal when contacting another surface or the amount of heat and wear created from a bearing surface.

A smoother surface will also be less sensitive for dirt and bacteria growth and will therefore be easier to clean, this is important in food processing industries.

In other situation a minimum friction or higher adhesion is desired which requires a higher surface roughness.

To be able to compare the different surface roughness it is usually measured in Ra or Rz and will be calculated in µm or µin according to ISO 21920-2:2021

Measurements are usually made using a mechanical gauge or a laser scanner.

Ra provides the calculated average deviation of the surface from the mean value (value if the surface was perfectly flat) of the sampling area.

Rz provides the average of variation in height between the highs and lows of 5 lines within the sample surface area

Rt shows the maximum deviation between highs and lows within the sample surface area.

Sampling Length is the benchmark’s length used to determine its surface roughness.

Evaluation length is the total sample length required to determine the roughness of the material and may include more than one sample length.

| Model | TIME ® 3200 | TIME ® 3202 |

|---|---|---|

| Roughness parameters | Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv,R3z, RS, RSm, RSk, Rmr, | Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv, R3z, RS, RSm,RSk, Rmr, Rpc, Rk, Rpk, Rvk, Mr1, Mr2 |

| Assessed profiles | Roughness profile (R) Primary profile (P) | Roughness profile (R) Primary profile (P) |

| Measuring system | Metric, imperial | Metric, imperial |

| Display resolution | 0.001 μm | 0.001 μm |

| Data output | RS232 | RS232 |

| Pickup measuring range | ±20μm, ±40μm, ±80μm | ±20μm, ±40μm, ±80μm |

| Cutoff length (L) | 0,25mm / 0,8mm / 2,5mm/Auto | 0,25mm / 0,8mm / 2,5mm/Auto |

| Evaluation length | 1~5L (selectable) | 1~5L (selectable) |

| Tracing length | 3-7L(selectable) | 3-7L(selectable) |

| Digital filter | RC, PC-RC, Gauss, D-P | RC, PC-RC, Gauss, D-P |

| Max. tracing length | 17,5mm/0.71inch | 17,5mm/0.71inch |

| Min. tracing length | 1,3mm/0.052inch | 1,3mm/0.052inch |

| Pick-up | Standard pickup TS100, inductive, diamond stylus radius 5μm, angle of stylus 90° | Standard pickup TS100, inductive, diamond stylus radius 5μm, angle of stylus 90° |

| Accuracy | ≤±10% | ≤±10% |

| Repeatability | ≤6% | ≤6% |

| Power | Li-ion battery rechargeable | Li-ion battery rechargeable |

| Dimensions (mm) | 140×52×48 | 140×52×48 |

| Weight | 440gr | 440gr |

The TIME 3200/3202 surface roughness gauges can be equipped with a number of optional extra's that facilitate various measurement setups.

A measuring stand consisting of:

|

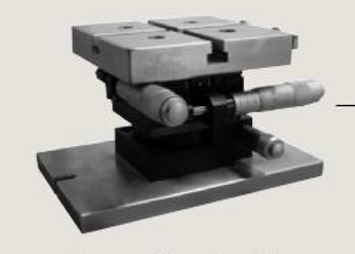

Leveling table for high accuracy measuringThe leveling table, TA630/TA631, can be used as part of the measuring table setup. |

|

Measuring platformThe measuring platform, TA620, forms the basis of the complete stand with fixation rail for the leveling table and adjustable hight. |

.jpg) |

L attachmentThe L attachment is used to mount the Time 3200 to the elevating tower. |

|

8mm adapterThe 8mm adapter mounts the device to the L bracket. |

|

Complete test standThis shows the complete test stand including the TIME 3200 surface roughness tester. |

A Printer:

|

PrinterThe TIME 3200/3202 can be connected to the TA230 printer to be able to produce the measurement results onsite. |

Optional pickups:

|

Standard pickup TS100TS100 standard pickup with skid for roughness test on plane surface, shaft and inner surface of holes with max. depth of 22mm, min diameter 5mm. |

|

Pickup for curved surfaces TS110TS110 pickup for curved surface used for roughness testing of curved surface with min curvature radius 3mm, working with measuring platform TA620. |

|

Small hole pickup TS120TS120 pickup for small holes used for roughness testing of small holes with min. 2mm diameter of inner surface, max. depth 9mm. |

|

Deep groove pickup TS130/131TS130: Used for roughness testing of deep groove with min. width 2mm, max. depth 3mm or of step with max. height 3mm, TS131: Used for roughness testing of deep groove with min. width 3mm, max. depth 10mm or of step with max. height 10mm, working with measuring platform TA620. |

|

right angled pickup TS140TS140 right-angled pickup Comprising right-angled pickup and right-angled transmit rod, used for roughness testing of groove and crank with min. width 7,5mm~20mm, and of steps with max. height 2,5mm, working with TA620. |

Specifications

| Roughness parameter | Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv, R3z, RS, RSm, RSk, Rmr, P |

| Assessed profiles | Primary profile (P), Roughness profile (R), Tp curve (material ratio Mr) |

| Profile recording magnification | Vv: 200x ~ 20000x , Vh: 20x, 50x, 200x |

| Standard | Conforms to ISO/DIN/JIS/ANSI (menu selectable) |

| Measuring system | Metric mm, imperial inch |

| Display resolution | 0,001µm / 0.04 µinch |

| Display | LCD 128 x 64 dot-matrix, with back-light |

| Dimensions LCD | 50mm x 30mm screen |

| Display features | Detector stylus position indicator, battery level indicator, direct display of parameters and profiles, direct printing, LCD brightness adjustment, auto-off after 5 minutes with auto-store, calibration through software (each cut-off) |

| Display languages | English, German, French, Italian, Spanish, Dutch |

| Data output | RS-232; direct to printer TA-220 or PC |

| Range | Ra, Rq : 0,005 - 16µmRz, Ry, Rp, Rt, R3z : 0,02 - 160µm, RSm, RS : 2 - 4000µm Tp : 1-100% (% Ry) |

| Cut-off length | 0,25mm / 0,8mm / 2,5mm |

| Evaluation length Ln | 1~5 cut-off |

| Tracing length Lt | (1~5 cut off) + 2 cut-off |

| Digital filter | RC, PC-RC, GAUSS, D-P |

| Detector | Standard model TS-100, Inductive, Diamond tip radius 5µm |

| Bores from diameter | 6,0mm, depth 15mm (TS-100) |

| Power | Li-ion battery rechargeable |

| Battery capacity | 1000mAh (>3000 measurements) |

| Charger | 220V, 50Hz |

| Operating temperature | 0°C ~ 40°C |

| Dimensions unit | 141mm x 56mm x 48mm |

| Weight | 480gr |

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request