3000FX SERIES Coating Thickness Gauge

The Checkline 3000FX series of coating thickness gauges is designed to deliver fast, non-destructive, and exceptionally precise measurements across a wide range of applications. Ideal for evaluating varnish, paint, and galvanic coatings on ferrous metals as well as paint, varnish, and anodised coatings on non-ferrous metals and even austenitic stainless steels, this series is an indispensable tool for ensuring a reliable and aesthetically pleasing finish on any product.

The Checkline 3000FX series of coating thickness gauges is designed to deliver fast, non-destructive, and exceptionally precise measurements across a wide range of applications. Ideal for evaluating varnish, paint, and galvanic coatings on ferrous metals as well as paint, varnish, and anodised coatings on non-ferrous metals and even austenitic stainless steels, this series is an indispensable tool for ensuring a reliable and aesthetically pleasing finish on any product.

Key Features:

- 3 Available Models:

- DCF-3000FX: Designed for measurements on ferrous metals.

- DCN-3000FX: Specialised for measurements on non-ferrous metals.

- DCFN-3000FX: Provides a combined solution for measurements on both ferrous and non-ferrous metals.

- Wide Measurement Range: Ranging from 0 to 1500 µm (0 to 60 mils), ideal for controlling coating thickness in various industrial applications.

- Multifunctional Interface: Fully menu-driven for fast, professional, and precise operation.

- High-Quality External Probes: Manufactured to extremely high standards and equipped with a unique hard-metal probe tip that minimises wear.

- Special Accessory: A V-notched footer provides a stable base for small cylindrical parts, which can be removed to reveal a "micro-probe" sensor perfect for measuring on small surfaces and components.

Key Benefits:

- Non-Destructive Measurement: Ensures that the surfaces evaluated remain undamaged during inspection.

- Precision and Reliability: Consistent results that guarantee a high-quality finish, essential for corrosion protection and mechanical performance.

- Versatility of Application: Ideal for a wide range of industries, from automotive to construction, where coating thickness is crucial for both aesthetics and functionality.

- Ease of Use: Its intuitive digital interface allows for simple control, whether in the laboratory or in the field, optimising time and productivity.

Contact us for more information or to place an order. Our team of experts is ready to assist you in selecting the coating thickness gauge that best meets your operational and technical requirements, ensuring precise and high-quality measurements in all your projects.

Features

- The 3000FX Series is a compact, lightweight coating thickness gauge for operators who require both innovative and user-friendly measuring techniques

- The 3000FX Series ensures non-destructive coating thickness measurement on steel and non Ferrous metals

- Data transfer to a printer or PC takes place via an infra-red interface

- A great number of readings can be statistically evaluated: number of readings, mean value, standard deviation, minimum and maximum reading. 200 readings can be stored in the memory.

- The 3000FX Series identifies the substrate and activates the appropriate measuring procedure.

- Menu in a choice of three languages ensures ease of operation

- The uniform contact pressure of the sensor is kept to a minimum, preventing scratches and indentations to sensitive surfaces.

- NIST Certificate Included at no additional cost

- Up to 10 000 readings can be statistically evaluated: number of readings, mean value, standard deviation, minimum and maximum reading.

- 1 Year Warranty

The 3000FX Series is supplied as a complete kit with:

- coating thickness gauge

- zero plate

- 2 calibration standards

- 2 AA batteries

- soft carrying pouch

- instruction manual

- manufacturer´s certificate

The DCF-3000FX is supplied with a

ferrous zero-plate

The DCN-3000FX is supplied with a

non-ferrous zero-plate

The DCFN-3000FX is supplied with a

ferrous and a non-ferrous zero-plate

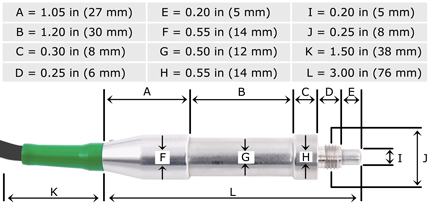

Dimensions

| Minimum Radius for Convex Surfaces | 3 mm | |

| Minimum Radius for Concave Surfaces | 5 mm | |

| Minimum Headroom | 100 mm | |

| Minimum Sample Diameter | 5 mm | |

| Minimum Substrate Thickness - F | 0,5 mm | |

| Minimum Substrate Thickness - NFe | 50 µm |

| Microns (µm) | |

|---|---|

| 0.0 - 99.9 µm | 0.1 µm |

| 100.0 - 249.8 µm | 0.2 µm |

| 250.0 - 499.5 µm | 0.5 µm |

| 500 - 999 µm | 1 µm |

| 1.000 - 1.998 mm | 0.002 mm |

| Mils | |

| 0.00 - 9.99 mils | 0.01 mils |

| 10.00 - 24.98 mils | 0.02 mils |

| 25.00 - 49.95 mils | 0.05 mils |

| 50.0 - 99.9 mils | 0.1 mils |

Related Products

Cic-Coating Gauge Calibration

- Service Return Form: Simplify the shipping process with our easy-to-use form, ensuring your equipment is handled correctly from the start.

- Accessibility: Located in the heart of Europe, we provide an accessible service for businesses across the continent.

More details

Accessories

CPS Certified Shim Set

- Wide Applicability: Suitable for a wide range of industries where precise coating thickness measurement is critical to product quality.

- Easy Integration: Compatible with a broad range of coating thickness meters, providing a comprehensive solution for calibration needs.

More details

3000-PTS Coating Thickness Gauge Test Stand

- Robust Construction: Manufactured with high-quality materials to ensure durability and resilience in industrial environments.

- Application Flexibility: Suitable for a wide range of industries requiring precise coating thickness measurements.

More details

Specifications

| Gauge versions: | DCF-3000FX for measurements on iron/steel DCN-3000FX for measurements on non-ferrous metals DCFN-3000FX for measurements on iron/steel and on non-ferrous metals |

| Measuring principle: | magnetic induction principle (Ferrous) eddy-current principle (Non-Ferrous) |

| Range: | 0 - 1500 µm (0 - 60.00 mils) |

| Accuracy: | ± 1µm (0.04 mils) + 1% of reading |

| Resolution: | 0.1 µm (0.004 mils) or < 2 % of reading |

| Display: | back-light, 4-digit alphanumeric, digit height: 10mm |

| Min. Measuring Area: | 5 mm x 5 mm (0.2" x 0.2") |

| Min. Curvature Radius: | convex: 3 mm (0.12") concave: 5 mm (0.2") |

| Min. Substrate Thickness: | Ferrous: 0.5 mm (20 mils) Non-Ferrous: 50 µm (2 mils) |

| Calibration: | factory calibration, zero calibration, foil calibration, offset-function: addition or subtraction of a constant value |

| Memory: | 200 readings |

| Statistics Program: | Number of readings, mean value, standard deviation, maximum and minimum reading of max. 10,000 readings |

| Data Output: | Infrared IrDA Standard |

| Operating Temp: | 0 °C to 50 °C (32 °F to 122 °F) -15 °C to 150 °C (with optional plastic footer) |

| Surface Temp: | -15 °C to 60 °C (5 °F to 140 °F) |

| Storage Temp: | -20 °C to +60 °C (-4 °F to 140 °F) |

| Power: | 2 AA - 1.5V |

| Dimensions: | 137 mm x 66 mm x 23 mm |

| Weight: | 205 g (7 oz) - gauge + probe |

| Protection Class: | IP 52 (proof against dust and dripping water) |

| Standards: | DIN, ISO, ASTM, BS |

| Warranty: | 1 year |

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request