GALVANOTEST GalvanoTest Coating Thickness Gauge

The GalvanoTest coating thickness gauge is a versatile and sophisticated thickness gauge working on the coulometric principle to measure virtually all types of electroplated single- or multilayer coatings such as chrome, nickel, brass, silver etc. on metal or non-metal substrates.

The GalvanoTest coating thickness gauge is a versatile and sophisticated thickness gauge working on the coulometric principle to measure virtually all types of electroplated single- or multilayer coatings such as chrome, nickel, brass, silver etc. on metal or non-metal substrates. The coulometric or anodic de-plating technique is used for measuring the thickness of electroplated coatings on virtually all substrates such as steel, non-ferrous metals or insulating material bases. Typical applications include nickel on steel, zinc on steel, tin on copper, silver on copper or copper on epoxy. This technique simply involves the removal of a small, barely visible area of coating material. The substrate is not affected. The coulometric method ensures highly reliable and accurate results.

To ensure easy operation of the instrument, the GalvanoTest requires no specific operator skills and only minimal training before actual measurements can take place. The coulometric principle is the only low-cost method to measure the individual layers of multi-layer systems, for instance chrome plus nickel plus copper on steel one after the other.

The GalvanoTest can be connected to the MiniPrint data printer to document measuring results and statistics. For specific measuring analysis or later reference, the characteristic voltage curve during the de-plating process can also be printed out.

The GalvanoTest gauge consists of three major components:

- Measuring cell - For measuring on even or curved surfaces up to 3 mm curvature radius, two different measuring cells are available. A measuring cell with circulating pump is connected to GalvanoTest 3000, a cell with air pulsator is connected to the 2000 model. The electrolyte is constantly moved around the measuring cell to ensure an even de-plating of the measuring area as well as on optimum use of the electrolyte. For measuring wires or small parts, an electrolyte cup is available to dip the samples into the electrolyte. The electrolyte cup can be used for both models and is available as an option.

- Stand - The stand serves to hold the test sample in place. It permits the exact positioning of the measuring cell on the test sample.

- Processing unit - GalvanoTest is a microprocessor based instrument with interactive LCD. It is suitable for measuring a variety of plating applications. The measuring application can be entered via touch-pad and visualized on a large alphanumeric display. Various data ports are available to connect GalvanoTest to peripheral units such as a PC, printer or Y-T recorder. For data transfer, an MSoft 7000 Basic Edition software is available as an option.

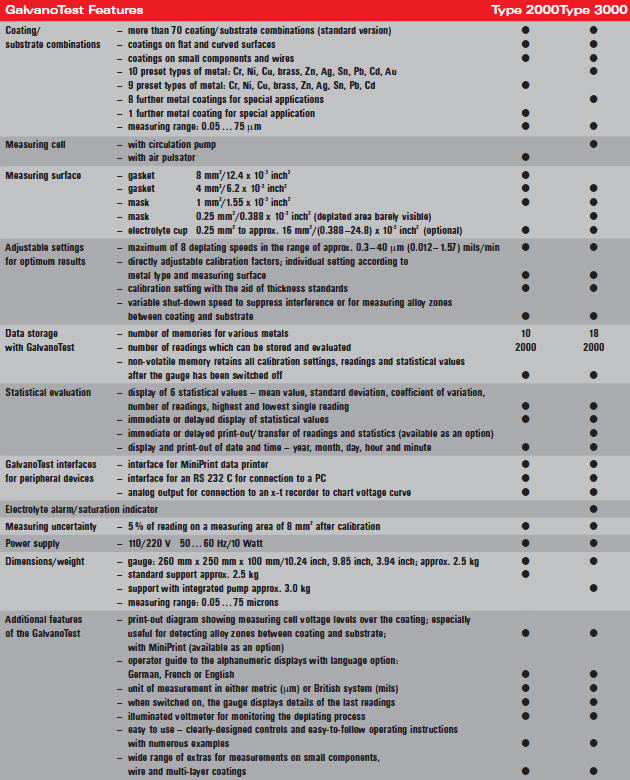

Features

- Universal coating thickness measurement for more than 70 combinations of coating and substrate

- Measurement of single and multi-layer coatings

- Exact measurement from 0.05 to 75 µm

- Suitable for nearly all electroplated coatings

- Coating thickness measurement on flat and curved surfaces

- Removal of a small area of coating material in an almost invisible area

- Flexible storage and evaluation of the measuring values

Complete Kit

The GalvanoTest 2000 is supplied as a complete kit including:

- GalvanoTest gauge

- Interface for connecting MiniPrint data printer or a PC

- Data port for Y-T recorder

- Standard measuring stand with measuring cell and pulsator nozzle

- Connecting cable gauge/ measuring stand

- A-gasket (8 mm2)

- B-gasket (4 mm2)

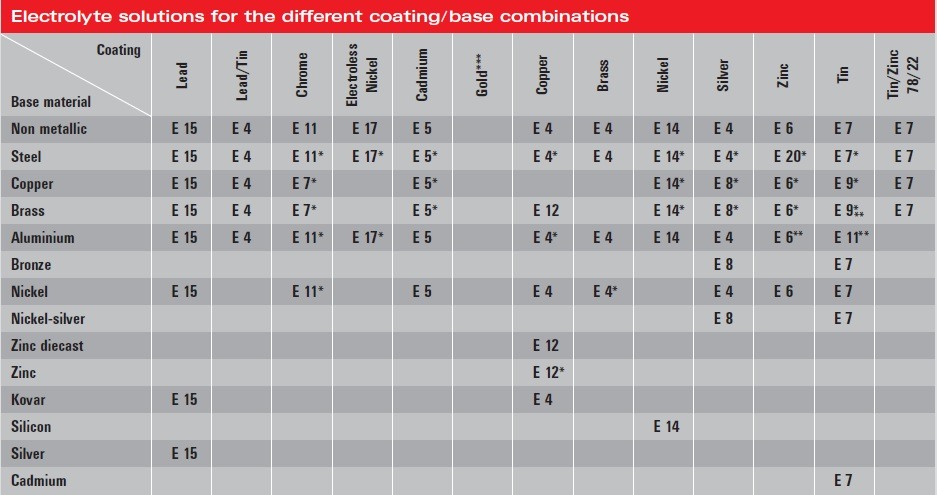

- 3 bottles electrolyte 100 ml each according to customer selection (except E12)

- Pipettes

- Bottle for electrolyte waste

- Spray bottle for distilled water

- Rubber pencil

- Absorbent paper package

- Operating Manual

The GalvanoTest 3000 is supplied as a complete kit including:

- GalvanoTest gauge

- Interface for connecting MiniPrint data printer or a PC

- Data port for Y-T recorder

- Measuring stand with integrated circulator pump incl. measuring cell type 1

- Connecting cable gauge/stand

- 2 B-gaskets (4 mm2)

- 20 C-masks (1 mm2) and 2 gaskets Ø 15 mm for sealing the masks

- 20 D-masks (025 mm2)

- 5 bottles electrolyte 100 ml each according to customer selection (except E12)

- Bottle for electrolyte waste

- Spray bottle

- Rubber pencil

- Absorbent paper package

- Operating manual

Electrolyte: E4, E7, E9, E11, E17 are categorized as hazarddous good - involves higher transport charges !

*Thickness standards are available ** Use internal cell type II *** Sample necessary (only GalvanoTest 3000)

Buy Now

Products

Product

Price

Quantity

134329

GalvanoTest 2000

134330

GalvanoTest 3000

All mentioned prices are excluding VAT & excluding shipment costs.

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request