POSITECTOR 6000FNDS - Coating Thickness Gauge for Duplex Coating Systems

![]() Range: 0 - 1500 µm

Range: 0 - 1500 µm

Minimum Zinc Thickness: 13 µm

Paint Layer Accuracy: +(1 µm + 1%) 0 - 50 µm / +(2 µm + 1%) > 50 µm

Zinc Layer Accuracy: +(2 µm + 1%) 0 - 50 µm / +(4 µm + 1%) > 50 µm

Temperature: up to 49° C

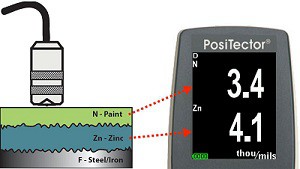

The PosiTector 6000 FNDS probe is designed to measure individual layer thicknesses of zinc and paint/powder in a duplex coating system with a minimum zinc layer thickness of 13µm.

The Zinc layer can be applied using several methods:

- Hot-dip galvanizing (most common for duplex coatings)

- Electro-galvanizing

- Zinc spray metallizing (thermal spray zinc)

The PosiTector 6000 FNDS probe measures the individual thicknesses of both the zinc and the paint layers in a duplex coating system with a single reading.

Two corrosion protection methods are better than one. That's the theory behind the Duplex Coating Systems, which combine the protection of galvanization with the benefits of an additional corrosion protection system, such as polymeric powder coating or paint.

Using paint or powder coating over galvanized steel (hot-dip, electro or zinc spray metallizing) can improve a substrate's ability to withstand the attack of corrosive substances in the working environment and extend the productive life of assets.

The result of using a combination of two protection methods is often better than the result of the individual protection method used independently.

In Duplex mode, the PosiTector 6000 FNDS utilizes both Magnetic (Ferrous) and Eddy current (Non-Ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses. The magnetic principle is used to measure the combined paint/zinc thickness over the ferrous substrate, and the Eddy current principle is used to measure the paint thickness over the Non-ferrous zinc coating. The zinc thickness is calculated by subtracting the paint thickness from the combined paint/zinc thickness measurement.

The PosiTector 6000 FNDS can also be taken out of ‘Duplex Mode’, allowing it to act as a PosiTector 6000 FNS probe to measure:

- Non-magnetic coatings on ferrous metals (steel)

- Non-conductive coatings on non-ferrous metals

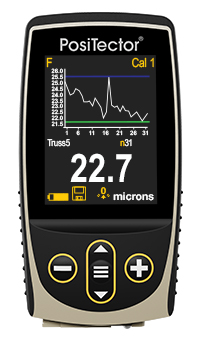

The 6000 FNDS probe is compatible with all PosiTector Advanced and Standard models with a color display.

Features

- Hi-Lo alarm audibly and visibly alerts when measurements exceed user-specified limits

- Reversible Display enables right side up viewing whether the gage is in your hand or on a work table

- Thick impact resistant Lexan® display is backlit for easy viewing in dim or dark environments

- No Calibration required for most applications

- Multi-lingual Menu; English, Spanish, French, German, Portuguese, Chinese, Japanese, Norwegian, Russian, Czech and Italian

- Built-in temperature compensation ensures measurement accuracy

- Average Zero Feature; allows for multiple "zero measurements" ideal for measurements on rough substrates

- User-selected units of mils, microns or mm

- High Resolution mode increases the displayed resolution for use on applications that require greater precision

- External probe for general purpose paint and coating applications

- Two (2) year warranty

- Made in the USA

Complete Kit

The PosiTector 6000 FNDS comes with:

- Standard or Advanced gauge body

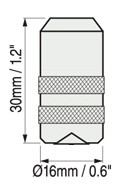

- FNDS probe

- Protective rubber holster with belt clip

- Wrist strap

- 3 AAA alkaline batteries

- Nylon carrying case with shoulder strap

- Protective lens shield

- USB cable

- Long Form Certificate of Calibration traceable to NIST or PTB

- Free Posisoft Desktop Software

| Feature Comparison Chart | Standard (1) |

Advanced (3) |

| Hi Contrast LCD Display |  Color |

Color |

| General Features | Standard (1) |

Advanced (3) |

| FAST mode - faster measurement speed for quick inspection | ||

| SCAN Mode - take continuous readings without lifting the probe | - |

|

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits |

|

|

| Instantly calculate average, standard deviation, min/max thickness and number of readings while measuring |

|

|

| Onscreen help, real time graphing, picture prompting and batch notes | - | |

| Memory Features & Capacity | Standard (1) |

Advanced (3) |

| Reading Storage Capacity | 1000 in one group | 250,000 in up to 1000 groups |

| Create meaningful batch names and enter notes directly on the instrument using a familiar on-screen QWERTY keyboard. | - | |

| SSPC PA2 feature set determines if film thickness over a large area conforms to user-specified min/max levels | - | |

| PSPC 90/10 feature determines if a coating system complies with an IMO performance standard for protective coatings | - | |

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | - | |

| Connection Options | Standard (1) |

Advanced (3) |

| USB port for fast, simple connection to a PC and to supply continuous power. USB cable included | ||

| WiFi technology wirelessly synchronizes with PosiSoft.net, downloads software updates, and connects to mobile devices for expanded functionality | - | |

| Bluetooth Wireless Technology for data transfer to a PC or optional portable printer | - | |

| PosiSoft Solutions | Standard (1) |

Advanced (3) |

| PosiSoft Desktop Software Desktop software for PC or Mac computer | ||

| PosiSoft USB Drive Access your PosiTector as a flash drive. View and print readings and graphs using universal PC/Mac web browsers or file explorers | ||

| PosiSoft.net (formerly PosiTector.net) Cloud-based application offering centralized management of PosiTector readings | ||

| PosiSoft Mobile Gage-based software application featured in all PosiTector Advanced instruments | - |

Specifications

| Measuring principle | Magnetic induction principle (Ferrous) Eddy-current principle (Non-Ferrous) |

| Display | Backlit & Reversible LCD |

| Data Output | USB - Standard & Advanced Models Bluetooth / WiFi - only the Advanced Models |

| Surface Temp. | Maximum: 49 °C |

| Power | 3 AAA batteries, Included |

| Protection Class | Meets or exceeds IP5X, Solvent, Acid, Oil, Water & Dust resistant |

| Calibration Certificate | Certificate of Calibration showing traceability to NIST included |

| Min. Concave Radius | 1 inch (2" OD) |

| Standards | ISO 2178/2360/2808, PrEN ISO 19840, ASTM B499/D1186/D1400/D7091/E376/G12, BS3900-C5, SSPC-PA2 and others |

| Dimensions | 137 x 61 x 28 mm |

| Weight | 140 gr |

| Warranty | 2 Years |

| FNDS | ||

|

||

| Range: | 0 - 1500 µm | |

| Minimum Zinc Thickness: | 13 µm | |

| Paint Layer Accuracy*: | ±(1 µm + 1%) 0 - 50 µm ±(2 µm + 1%) > 50 µm |

|

| ZincLayer Accuracy*: |

±(2 µm + 1%) 0 - 50 µm |

|

*Accuracies are stated as a fixed value plus a percentage of the gauge's actual reading.

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request