X SERIES High Performance Durometer

The X-Series Asker Hardness testers are portable, easy to use, make non-destructive measurements and can be equipped (optional) with peak indicators. The Asker High Performance series has an accuracy of ±.75 point and is available in Type F for soft materials like sponge rubber and urethane foam.

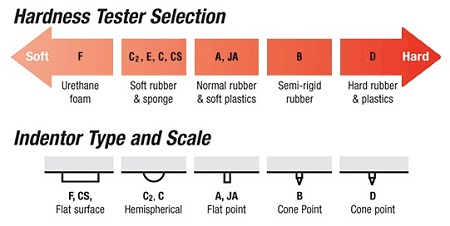

Common Hardness scales:

- Model X-A Shore A Hardness - Normal Rubber

- Model X-D Shore D Hardness - Hard Rubber and plastics

- Model X-C Asker C Hardness - Soft rubber and sponge

- Model X-F Asker F Hardness - Urethane foam, sponge and polystyrene foam

Special Hardness Scales:

- Asker JA Normal rubber & softer plastics

- Asker B semi rigid rubber & plastics

- Asker C2 Soft rubber & sponge Asker

- Asker CS Polystyrene foam

- Asker E Soft & cellular rubber

Supplied with 3 point NIST traceable calibration cert.

Asker models are available in ASTM D 2240 durometer Types: Shore A Hardness, Shore D Hardness and Asker C Hardness durometer scales.

Conforms to:

JIS K 6253, JIS K 7215, ASTM D 2240, ISO 7619, ISO 868, DIN 53505

All X models are supplied with a NIST traceable calibration certificate.

All X models are supplied with a NIST traceable calibration certificate.

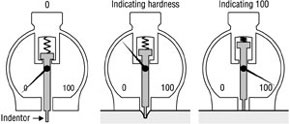

As the hardness tester is pressed against the sample, the material resistance force and indenter spring load balance. The depth of the indenter is measured, which provides a measure of the material's hardness. Values are based upon a 100 point scale (accuracy ±.75 point). However, as time elapses the indicator will "creep" back so that a reading taken a few seconds after the tester makes contact with the sample will be less than the peak reading. The optional peak indicator helps to more closely monitor the difference between peak and "creep" in hardness tests.

Specifications

| Indication Range: | 262 degree dial scale |

| Minimum indication: | 1 point (Accuracy : ± 1 point) |

| Pressure foot Dimensions: | 44 ×18 mm rectangular |

| Outer Dimensions: | Approx. Width 57 × Depth 30 × Height 76 mm |

| Mounting Thread: | M6 P1 |

| Weight: | 200 grams |

Related Products

Cic-Duro Durometer Calibration

- Exclusively NIST-certified testing equipment

- Possibility to adjust and repair

More details

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request