R01 SERIES S-Beam Force Sensor

![]() The Series R1 Force sensor is designed for tension and compression testing in a broad variety of industries and /or laboraties. It has a rugged S-beam design that is equipped with threaded holes on top and bottom.

The Series R1 Force sensor is designed for tension and compression testing in a broad variety of industries and /or laboraties. It has a rugged S-beam design that is equipped with threaded holes on top and bottom.

It uses the Plug & Test® system to connect to a Mark-10 Indicator, 3I, 5I, 7I or a Series F test stand. This system has the benefit of an internal pcb which stores calibration and configuration, this makes an indicator interchangeable during testing.

The R01 series is available in a range of 11 different capacities from 250 N to 50 kN. The R01 comes with a NIST-traceable certificate of calibration with data is included. Standard cable length is 6 m but for test stand use a suffix -1 can be added to the model number, a version with a 254mm cable will be shipped.

Features

- Unique Plug & Test connector holds all calibration and configuration data

- Measures tensile and compressive forces

- NIST-traceable certificate of calibration included

- Durable S-beam load cell

- Capacities available from 250 N to 50 kN

- Two threaded holes on each side

General information

Mark-10 M7I, M5I, and M3I indicators are used in combination with Plug & Test® sensors and can therefore accommodate numerous force and torque measurement requirements, from 1 N to 50 kN (0.25 to 10,000 lbF) of force, and from 7 Ncm to 550 Nm (10 ozFin to 5,000 lbFin) of torque.

Plug & Test® sensors can be used handheld or mounted to a fixture or test stand for more accurate and repeatable testing results.

The sensors are separately calibrated therefore they can be disconnected from one indicator and connected to another without the need for re-calibration or re-configuration as this is stored in the PCB located inside the smart connector.

Accuracy

System accuracy is determined by the combination of Indicator and sensor combined. To determine the total system accuracy the accuracy value of the sensor is added to the value of the indicator.

As the Indicators have different accuracy values the total system accuracy may vary between the different indicator/sensor combinations. Indicator Model Accuracy M7I / M5I ±0,1% of full scale M3I ±0,2% of full scale.

Example 1 Model MR01-100 sensor with Model M5I Indicator MR01-100 ±0,15% of full scale + M5I ±0,1% of full scale = Total ±0,25% of full scale This translates into a fixed error of up to: 0,25% x 500 N = 1,25 N

Example 2 Model MR50-50Z sensor with Model M3I Indicator MR50-50Z ±0,35% of full scale + M3I ±0,2% of full scale = Total ±0,55% of full scale This translates into a fixed error of up to: 0,55% x 50 Ncm = 0,275 Ncm

Because accuracy is defined as a percentage of full scale, the fixed error is possible anywhere on the scale from 0 to the capacity. As such, this value represents an increasingly large error as percentage of reading towards the low end of the scale. It is, therefore, recommended that a sensor is selected with capacity as close as possible to the expected load. The resolution may be different for some sensors depending on whether a M7I, M5I, or M3I indicator is being used. For example, a Series R01 force sensor will display finer resolution when connected to a M5I indicator than when connected to a M3I indicator.

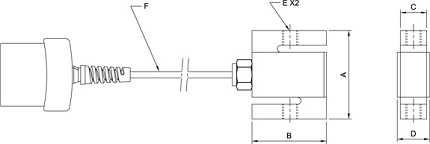

Dimensions

| Model | A | B | C | D | E |

|---|---|---|---|---|---|

| MR01-200 | 2.40 [61.0] | 2.00 [50.8] | 0.46 [11.7] | 0.90 [22.9] | 1/4-28 UNF |

| MR01-200 | 2.40 [61.0] | 2.00 [50.8] | 0.46 [11.7] | 0.90 [22.9] | 1/4-28 UNF |

| MR01-200 | 2.40 [61.0] | 2.00 [50.8] | 0.46 [11.7] | 0.90 [22.9] | 1/4-28 UNF |

| MR01-300 | 2.40 [61.0] | 2.00 [50.8] | 0.71 [18.0] | 1.10 [27.9] | 1/2-20 UNF |

| MR01-500 | 2.40 [61.0] | 2.00 [50.8] | 0.71 [18.0] | 1.10 [27.9] | 1/2-20 UNF |

| MR01-750 | 2.40 [61.0] | 2.00 [50.8] | 0.71 [18.0] | 1.10 [27.9] | 1/2-20 UNF |

| MR01-1000 | 2.40 [61.0] | 2.00 [50.8] | 0.71 [18.0] | 1.10 [27.9] | 1/2-20 UNF |

| MR01-1500 | 2.40 [61.0] | 2.00 [50.8] | 0.96 [24.4] | 1.40 [35.6] | 1/2-20 UNF |

| MR01-2000 | 2.40 [61.0] | 2.00 [50.8] | 0.96 [24.4] | 1.40 [35.6] | 1/2-20 UNF |

| MR01-5000 | 3.90 [99.1] | 3.00 [76.2] | 0.96 [24.4] | 1.40 [35.6] | 3/4-16 UNF |

| MR01-10000 | 3.90 [99.1] | 3.00 [76.2] | 1.21 [30.7] | 1.63 [41.4] | 3/4-16 UNF |

MR01-XXXXX: 20 ft [6 m] - MR01-XXXX-1*: 10 in [254 mm]* *Add suffix “-1” for shortened cable, for use on ESM1500, ESM750, ESM303, and ESM303H test stands. Ex: MR01-1000-1. Test stand mounting hardware is included. Note that MR01-5000 and MR01-10000 cannot be mounted to the ESM303 or ESM303H test stands. |

|||||

| Model | kN | N | kgF | gF | ozF | lbF |

|---|---|---|---|---|---|---|

| MR01-50 | - | 250 x 0,1 | 25 x 0,01 | 25000 x 10 | 800 x 0,5 | 50 x 0,02 |

| MR01-100 | - | 500 x 0,2 | 50 x 0,02 | 50000 x 20 | 1600 x 1 | 100 x 0,05 |

| MR01-200 | 1 x 0,0005 | 1000 x 0,5 | 100 x 0,05 | - | 3200 x 2 | 200 x 0,1 |

| MR01-300 | 1.5 x 0,001 | 1500 x 1 | 150 x 0,1 | - | 4800 x 5 | 300 x 0,2 |

| MR01-500 | 2.5 x 0,001 | 2500 x 1 | 250 x 0,1 | - | 8000 x 5 | 500 x 0,2 |

| MR01-750 | 3.75 x 0,002 | 3750 x 2 | 375 x 0,2 | - | 12000 x 10 | 750 x 0,5 |

| MR01-1000 | 5 x 0,002 | 5000 x 2 | 500 x 0,2 | - | 16000 x 10 | 1000 x 0,5 |

| MR01-1500 | 7.5 x 0,005 | 7500 x 5 | 750 x 0,5 | - | 24000 x 20 | 1500 x 1 |

| MR01-2000 | 10 x 0,005 | 10000 x 5 | 1000 x 0,5 | - | 32000 x 20 | 2000 x 1 |

| MR01-5000 | 25 x 0,01 | 25000 x 10 | 2500 x 1 | - | - | 5000 x 2 |

| MR01-10000 | 50 x 0,02 | 50000 x 25 | 5000 x 2 | - | - | 10000 x 5 |

| Model | kN | N | kgF | lbF |

|---|---|---|---|---|

| MR01-50 | - | 250 x 0,5 | 25 x 0,05 | 50 x 0,05 |

| MR01-100 | - | 500 x 0,5 | 50 x 0,05 | 100 x 0,1 |

| MR01-200 | - | 1000 x 1 | 100 x 0,1 | 200 x 0,2 |

| MR01-300 | - | 1500 x 2 | 150 x 0,2 | 300 x 0,5 |

| MR01-500 | - | 2500 x 2 | 250 x 0,2 | 500 x 0,5 |

| MR01-750 | - | 3750 x 2 | 375 x 0,2 | 750 x 0,5 |

| MR01-1000 | - | 5000 x 5 | 500 x 0,5 | 1000 x 1 |

| MR01-1500 | - | 7500 x 10 | 750 x 1 | 1500 x 2 |

| MR01-2000 | - | 10000 x 10 | 1000 x 1 | 2000 x 2 |

| MR01-5000 | 25 x 0,02 | - | 2500 x 2 | 5000 x 5 |

| MR01-10000 | 50 x 0,05 | - | 5000 x 5 | 10000 x 10 |

Specifications

| Accuracy: | ± 0.15% of full scale + indicator |

| Weight: | From 0.9 kg to 1.4 |

| Warranty: | 3 years |

Related Products

Model-3I Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 2.000 Hz sampling rate

- Ultra-compact size

More details

Model-5I Advanced Digital Force/Torque Indicator

- Interchangeable force and torque sensors through, separately sold, Plug & Test® technology

- High-speed 7.000 Hz sampling rate

- USB, RS-232, Mitutoyo, and analog outputs

More details

Model-7i Advanced Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 14.000 Hz sampling rate

- Continous data capture of up to 5.000 data points, at up to 14.000 Hz, downloadable to a PC

- 5 units of measurement, plus Coefficient of Friction and user-defined unit with configurable name

More details

Cic-Force Calibration Force Gauge

- Short turnaround

- Exclusively in accordance with Deutscher Kalibrierdienst (DKD) working standards, class F1; calibration-no: 19026 - 07

- Possibility to adjust and repair

More details

ESM303 Motorized Teststand with PC Control

- Selectable speed setting

- Stepper motor-driven, producing smooth and quiet operation with no speed variation under load

More details

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request