POSITECTOR GLS Portable Gloss Meter

![]() The PosiTector GLS Gloss Meter (GLS) is a portable electronic device designed to measure the specular reflectance and gloss of surfaces. It includes a body, available in either Standard or Advanced models, and a probe.

The PosiTector GLS Gloss Meter (GLS) is a portable electronic device designed to measure the specular reflectance and gloss of surfaces. It includes a body, available in either Standard or Advanced models, and a probe.

Conforms to

- ASTM C584/D523/D4039,

- ISO 2813/7668,

- DIN 67530,

- JIS Z 8741,

- AS/NZS 1580.602.2

The PosiTector body automatically detects the attached probe and performs a self-check. To disconnect a probe from the body, slide the plastic probe connector horizontally in the direction indicated by the arrow, away from the body. To attach a different probe, simply reverse these steps. It is not necessary to power down the device when switching probes.

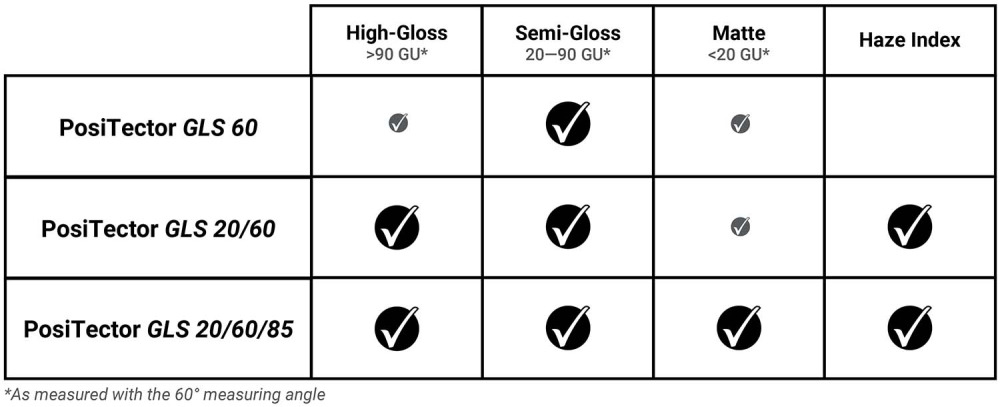

The PosiTector GLS Gloss Meter is available in three models:

- PosiTector GLS 60°: Ideal for most gloss applications and the preferred angle for semi-gloss.

- PosiTector GLS 20°/60°: Suitable for high- to semi-gloss applications. Calculates the Haze Index, which is the arithmetic difference between the specular reflectance measured at 60° and 20°

- PosiTector GLS 20°/60°/85°: Suitable for high-gloss, semi-gloss, and matte gloss applications. Also calculates the Haze Index, based on the difference between the specular reflectance measured at 60° and 20°.

The Haze Index is a measure used in gloss measurement to quantify the haziness or milkiness of a surface. It is calculated as the difference in specular reflectance between measurements taken at two different angles, typically 60° and 20°. Specifically, the Haze Index is the arithmetic difference between the gloss readings at these angles.

The Haze Index helps to differentiate between surfaces that may have similar gloss levels but differ in terms of clarity and sharpness of reflections. A higher Haze Index indicates a surface that scatters light more diffusely, resulting in a less clear reflection, while a lower Haze Index indicates a surface with clearer, sharper reflections. This metric is particularly useful in industries where the appearance and quality of a surface finish are critical.

Glossy surfaces are widely favored across various industries, from automotive and electronics to baby toys. Gloss often symbolizes luxury and wealth, which could stem from a biological association with water, as glossy objects might subconsciously remind us of the appearance of water.

Industrial Importance of Gloss

Gloss, defined as an optical property that indicates how well a surface reflects light in a mirror-like direction, can significantly influence a product's perceived quality. While many industries prefer a glossy finish, others may require a matte finish.

Why Measure Gloss?

Monitoring gloss during manufacturing can improve the production process by identifying issues, ensuring consistency, reducing waste, and enhancing quality. Factors like surface texture, coating properties, and paint application can impact a coating's appearance. Even small variations in gloss, though sometimes hard to detect visually, can affect process control and product quality.

What is Reflectance?

When light hits a surface, some is absorbed while some is reflected. Reflectance refers to the reflected light, which determines how we perceive the object. On smooth surfaces, like mirrors, light is reflected in a specific direction (specular reflection), whereas on rough surfaces, light scatters in multiple directions.

Percent Reflectance and Gloss Units

Reflectance is measured as the percentage of reflected light compared to the emitted light. Gloss meters, such as the PosiTector GLS, can display measurements in Gloss Units (GU) or as a percentage of reflectance. According to ISO 2813, Gloss Value is the ratio of the reflectance of a test specimen to that of a standard polished black glass surface, multiplied by 100, expressed in Gloss Units.

Understanding Haze Index

Haze, perceived as a "milky" halo on reflective surfaces, is caused by microscopic surface imperfections. The Haze Index, defined by ASTM D4039, is the difference between gloss measurements taken at 60° and 20°. It can be calculated using gloss meters like the PosiTector GLS 20/60 and 20/60/85.

Gloss Measurement Techniques

Digital gloss meters, such as the PosiTector GLS, use a calibrated light source and sensor placed at specular angles. The amount of light energy received by the sensor compared to that emitted by the source determines the reflectance, which is then used to calculate gloss.

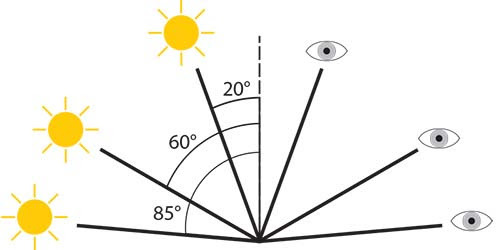

Choosing the Correct Measurement Angle

Gloss measurement involves selecting the appropriate angle based on the surface's Gloss Unit (GU) reading at a 60° angle:

- Semi-gloss surfaces (10–70 GU): Use 60°.

- High-gloss surfaces (>70 GU): Use 20°.

- Matte surfaces (<10 GU): Use 85°.

The PosiTector GLS offers multiple modes and features:

- HiLo Mode: For quick inspection or pass/fail checks.

- Differential Mode: Calculates the difference between the current reading and a reference value.

- Normal Scan Mode: Measures and saves up to 120 readings per minute.

- Statistics Scan Mode: Provides real-time statistics and saves each scan.

As part of the PosiTector platform, the GLS can also function with other PosiTector probes for various measurement needs. It includes a large touchscreen, and Advanced models offer WiFi or Bluetooth connectivity for data management.

Data Management with PosiSoft Software

After gloss measurements, data can be downloaded via USB or WiFi for advanced models. PosiSoft Desktop software enables viewing, printing, and creating customized reports of the data.

Features

- Featuring a larger 2.8" impact-resistant color touchscreen, the device offers a redesigned keypad for easy and quick menu navigation.

- The gauge body is built to be weatherproof, dustproof, and water-resistant, boasting an IP65-rated enclosure.

- Upon power-on, the device automatically performs diagnostics and auto-calibration using a protective base plate with an integrated calibration standard (tile).

- It provides rapid measurement speeds of over 60 readings per minute and includes two powerful scan modes for assessing large surfaces (available in advanced models only).

- Connectivity options include USB, WiFi, and Bluetooth, compatible with PosiSoft PC, Mac, and smartphone software.

- A Certificate of Calibration, showing traceability to NRC for both the probe and gloss standard, is also included.

Complete Kit

The GLS Kit comes with

- Protective base plate with integrated calibration standard (tile)

- 10 Cleaning wipes

- Protective rubber holster

- Wrist strap

- 3 AAA batteries

- Instruction manual

- Hard shell case

- Protective lens shield

- USB cable

- PosiSoft Software

- Long Form Certificate of Calibration

Specifications

| Measurement Area | 20°: 10 x 10 mm 60°: 10 x 20 mm 85°: 4 x 45 mm |

| Measurement Range | 20°: 0 - 2,000 GU 60°: 0 - 1,000 GU 85°: 0 - 160 GU |

| Repeatability | ±0.2 GU (≤100 GU), ±0.2% (>100 GU) |

| Reproducibility | ±0.5 GU (≤100 GU), ±0.5% (>100 GU) |

| Resolution Gloss | ±0.1 GU (≤100 GU), ±1 GU (>100 GU) |

| Resolution % Reflectance | 0.1% |

| Resolution Haze | ±0.1 (≤100), ±1 (>100) |

| Operating Conditions | 0° to 45° C - non-condensing |

| Probe Size | 165 x 73 x 32 mm |

| Probe Weight | 555 g |

| Warranty | 2 years |

| Gloss Range | 60° value | Measure with | |

|---|---|---|---|

| High Gloss | > 70 GU | 20° | |

| Semi Gloss | 10 – 70 GU | 60° | |

| Low/Matte | ≤ 10 GU | 85° |

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request