PT-UTG Ultrasonic Thickness Gauge

![]() Advanced Precision for Industrial Environments

Advanced Precision for Industrial Environments

Explore the PT-UTG from Checkline, an ultrasonic thickness gauge designed to precisely measure wall thickness and assess corrosion on materials such as steel, plastic, and others. Ideal for applications where access is limited to one side, this device is essential for inspecting pipes, tanks, and similar structures.

Key Features:

- Thru-Paint Technology: Allows for the measurement of metal thickness under the coating without the need to remove it, optimizing inspection time and costs.

- Robust Construction: Designed to withstand harsh industrial environments with resistance to solvents, acids, oils, water, and dust.

Special Features:

- Large and Clear LCD Display: Facilitates the reading of measurements and menu navigation, even in low-light environments.

- Extensive Storage Capacity: Can store up to 100,000 readings, allowing for detailed and efficient data management.

User Benefits:

- Ergonomic and Portable Design: Compact and easy to handle, ideal for quick and efficient measurements in the field or laboratory.

- Compatibility with Multiple Probes: Accepts probes for a variety of applications, increasing its versatility.

The PT-UTG from Checkline is a reliable and precise solution for those who need detailed and consistent thickness measurements, providing cutting-edge technology in an accessible and easy-to-use design.

Step 1: Select a body

(Standard or Advanced features)

| Standard (1) | Advanced (3) |

|---|---|

|

|

| Feature | Standard (1) | Advanced (3) |

|---|---|---|

| Hi Contrast LCD Display | Monochrome | Color |

| Reading Storage Capacity | 250 in one group | 100,000 in up to 1000 groups |

| Statistics - Instantly calculate average, standard deviation, min/max thickness and number of readings while measuring | ||

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits | ||

| Min Scan - measurement rate of up to 20 readings per second with on-screen min and max for quick inspection over a large area | ||

| A Scan - with adjustable Gain with screen capture for further analysis and documentation | - | |

| B Scan - display in which a cross sectional profile of the test material is represented | - | |

| Batch Annotation - Create meaningful batch names and enter notes directly on the instrument using a familiar on-screen QWERTY keyboard. | - | |

| Bluetooth Wireless Technology for data transfer to a PC or optional portable printer | - | |

| Onscreen help, real time graphing, picture prompting and batch notes | - |

Step 2: Select Probe Style

Corrosion Probe

Measures the wall thickness of materials such as steel, plastic and more. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side

Measures the wall thickness of materials such as steel, plastic and more. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side

- 5 MHz dual element transducer with wear resistant PEEK probe tip

- Automatic V-Path compensation for thin materials

Multiple-Echo Probe

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

- 5MHz contact probe with wear resistant Alumina probe tip

- Multiple Echo technique averages 3 or more echoes for accurate and reliable readings

- Most accurate method to measure remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense.

- Toggle easily between:

- Multiple Echo mode to eliminate coating thickness

- Single Echo mode to detect pits and flaws, and to increase the measurement range

| Corrosion (UTG-C) | Multiple Echo (UTG-ME) | ||

|---|---|---|---|

| Type of probe | Dual 5 MHz element | 5 MHz contact | |

| Pass-through paint capacity (Multiple echo) |

No | Yes | |

| Measuring range* (Single echo) |

0.040" to 5.000" 1.00 to 125.00 mm |

0.100" to 5.000" 2.50 to 125.00 mm |

|

| Measuring range* (multiple echo) |

N/A | 0.100" to 2.500" 2.50 to 60.00 mm |

|

| Resolution | 0.001" / 0.01 mm | 0.001" / 0.01 mm | |

| Accuracy | ±0.001" / ±0.03 mm | ±0.001" / ±0.03 mm | |

| *Measuring range is for carbon steel and depends on surface condition, temperature and material. | |||

Color Model (3) Only. A display in which the received pulse amplitude is represented along y axis and the travel distance of the ultrasonic pulse is represented along the x axis.

Color Model (3) Only. A display in which a cross sectional profile of the test material is represented.

| Material (Menu Option) | Longitudinal Velocity | Min Range* | Max Range* | |||

|---|---|---|---|---|---|---|

| in/us | m/s | in | mm | in | mm | |

| CAST IRON (Iron) | 0.179 | 4547 | 0.040 | 1.02 | 5.000 | 127.00 |

| SS 303 (SS303) | 0.223 | 5664 | 0.040 | 1.02 | 5.000 | 127.00 |

| STEEL 1018 (Steel) | 0.233 | 5918 | 0.040 | 1.02 | 5.000 | 127.00 |

| Al 2024 (Alum) | 0.251 | 6375 | 0.050 | 1.27 | 5.000 | 127.00 |

| PLEXIGLAS (Plexi) | 0.106 | 2692 | 0.040 | 1.02 | 2.000 | 50.80 |

| PVC (PVC) | 0.094 | 2388 | 0.035 | 0.89 | 2.000 | 50.80 |

| POLYSTYRENE (Poly) | 0.081 | 2057 | 0.035 | 0.89 | 2.000 | 50.80 |

| * Range may change depending on surface roughness, Temperature or Material Properties | ||||||

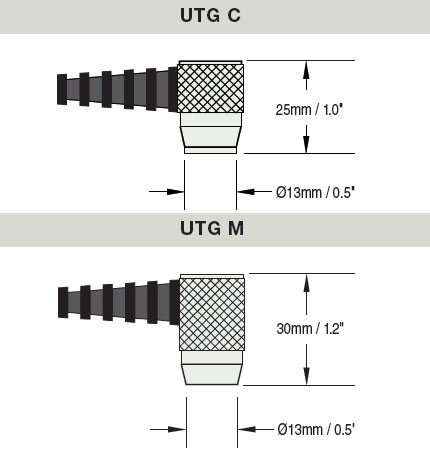

Dimensions

Complete Kit

Related Products

TI-25M Ultrasonic Wall Thickness Gauge

- Simple operator controls

- Resolution of 0.001 inch (0,01 mm)

More details

TI-25M-MMX Through Paint Ultrasonic Wall Thickness Gauge

- Resolution of 0.01 mm (0.001 inch)

- Simple operator controls virtually eliminate training

- Ability to measure through paint and eliminate coatings

More details

CIC-WALL Wall Thickness Gauge Calibration Service

- Easy planning of calibration

- Short turnaround

- Exclusively in accordance with DIN 55 350 Part 18, § 4.2.2, DIN ISO 8402 Part 1

More details

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request