MINITEST 735 Coating Thickness Gauge with external probes connected via cable

The model MiniTest 735 comes with an external sensor.

The model MiniTest 735 comes with an external sensor.

The MiniTest 735 coating thickness gauge is the solution to all your coating thickness problems where a reliable finish and perfect product appearance play a major role for long-term value and success, e.g. in the automotive and shipbuilding industry, steel- and bridge construction or in the electroplating industry, to name a few industries.

The MiniTest 735 is ergonomically designed and its rounded shape allows the MiniTest gauge to fit perfectly into the palm of your hand. It also features a measuring speed setting option that allows adjustment to changing requirements for utmost efficiency and optimum productivity: taking many readings in a short time with medium precision or taking only a few readings with increased accuracy.

The MiniTest 735 facilitates non-destructive coating measurement of non-magnetic coatings (paint, synthetic material, chromium etc.) on ferromagnetic substrates (steel) and of insulating coatings (varnish, enamel, synthetic material, anodizing aluminum etc.) on conductive substrates (aluminum, copper, austenitic stainless steel).

Its sensors perfectly compensate for irregular shaped surfaces thanks to the predefined calibration methods that are available to adapt to a wide range of different surface conditions and accuracy requirements.

The MiniTest 735 gauge is equipped with the new SIDSP® sensors.

SIDSP® is a world wide leading technology for coating thickness sensors. With this new technology, another new benchmark for innovative coating thickness measurement has been set.

SIDSP® stands for Sensor-Integrated Digital Signal Processing:

A technology where the signals are completely processed into digital form inside the sensor at the time and point of measurement.

SIDSP® sensors are manufactured according to completely new state-of-the-art production techniques.

Unlike conventional techniques, the SIDSP® sensors create and control the excitation signals for the sensor head inside the sensor. The return signals are directly digitally converted and processed at a 32 bits accuracy to give you the complete coating thickness value. For this technique, highly sophisticated methods of digital signal processing are used as known from modern telecommunication technologies (mobile phone networks) such as digital filters, base band converting, averaging, stochastic analysis, etc. This enables the user to achieve a signal quality and precision unmatched so far with analogue signal processing. The thickness value is digitally transmitted via the sensor cable to the display unit. Setting a new standard in coating thickness measurement, this technology offers decisive advantages and improvements compared to the commonly used analogue sensors.

The new SIDSP® sensors guarantee the following:

- High stability of measuring signals

- SIDSP® sensors’ characteristic curves feature high accuracy

- SIDSP® sensors provide excellent adaptability

- SIDSP® N and FN sensors compensate for substrate conductivity

- SIDSP® sensors are highly insensitive to changes in temperature

- SIDSP® sensors are wear-resistant

- Future-oriented solutions

The delivery of the device includes the data transfer software MSoft 7 basic.

Features

- Correct readings with interference free measurement with precise evaluation through SIDSP®

- External sensor

- Automatic substrate identification with FN sensors

- Efficient temperature compensation

- High precision characteristic curves achieved during the manufacturing process by calibrating up to 50 calibration points

- Large memory capacity for storing up to 10,000 readings

- Readings and statistical values can be called-up individually

- Easy menu-guided operation, 20 menu languages available

- Measurement data can be transferred by Bluetooth or USB to PCs, tablets or smart phones.

- Future-proof through downloadable sensor and gauge software updates

- Audible and visual (red and green LED) alarms

- Large, easy-to-read backlit graphics display

- Display orientation can rotate 180° so readings will never be upside down

- Factory set, zero, 2-point, 3-point and roughness calibration

- SSPC-PA2, ISO, Swedish (SS 18 41 60), Australian (AS 3894.3), ISO 19840 and ASTM D 7091 (formerly D 1186 and D 1400)

Specifications

| Sensor Type | External sensor |

| Substrate Identification | Yes, with FN sensors |

| SIDSP® sensor | Yes, for increased accuracy and reproducibility |

| Sensor characteristics | High-accuracy sensor characteristics through up to 50 calibration points during the sensor manufacture |

| Individual temperature compensation | Yes |

| Number of memories | 10, user-definable memory arrangement according to batches |

| Total memory capacity | max. 10,000 |

| Memory batches | Include readings, a defined calibration mode, parameters and statistics calculated from batch readings |

| Statistical evaluation | Number of readings, minimum, maximum, mean value, standard deviation, coefficient of variation |

| Single reading statistics | Block value statistics (norm-conforming/ user-configurable), stored readings and statistical values can be called seperately, print-out readings and statistics on MiniPrint 7000 data printer, transfer of readings and statistics to a PC |

| Calibration modes | Factory calibration, zero-point, 2-points, 3-point calibration, calbiration method "rough", user-adjustable off-set value, user-adjustable correction value for substrate roughness |

| International calibration procedures | ISO, SSPC, "Swedish", "Australian" |

| Measuring units | metric (μm, mm, cm) / imperial (mils, inch, thou) switchable |

| Display | Large graphical display, backlit, 180° rotatable |

| Menu | User-friendly, 25 languages |

| Software | Sensor and gauge software updates available via download |

| Measuring rate/ accuracy | User adjustable to standard, quick, high precision |

| Thickness identification | Continuous mode for quick identification of changes in thickness |

| Automatic switch-off | Battery saving mode with adjustable switch-off mode |

| Protection | IP40 |

| Operating temperature | –10°C - 60°C |

| Storage temperature | – 20°C - 70°C |

| Data interfaces | Bluetooth® 4.0, Bluetooth Smart®, Mini-USB |

| Power supply | 2 x AA (Mignon cells), rechargeable NiMH accu batteries type AA/HR6 (as an option) |

| Norms and standards | DIN EN ISO 1461, 2064, 2178, 2360, 2808, 3882, 19840, ASTM B 244, B 499, D7091, E 376, AS 3894.3, SS 1841 60, SSPC-PA 2 |

| Dimensions | 157 mm x 75,5 mm x 49 mm |

| Weight | approx. 210 g |

| Warranty | 1 year |

For measuring coating thickness on ferrous metals

Measuring principle: Magnetic induction principle (Ferrous)

Sensor Model N:

For measuring coating thickness on non-ferrous metals

Measuring principle: Eddy-current principle (Non-Ferrous)

Sensor Model FN:

For measuring coating thickness on ferrous & non-ferrous metals

Measuring principle: Magnetic induction principle & Eddy-current principle

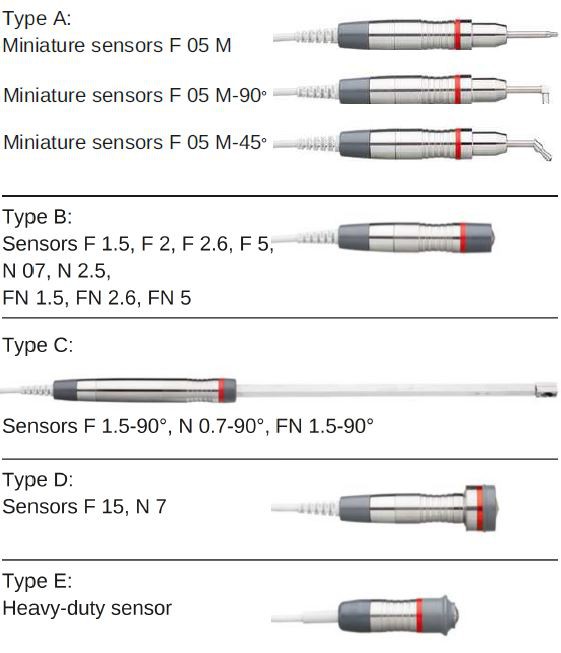

| Measuring procedure | Sensor model | Type | Measuring range |

Uncertainty (of reading) |

Minimum measuring spot | MiniTest 725 | MiniTest 735 | MiniTest 745 |

|---|---|---|---|---|---|---|---|---|

| Magnetic-induction sensors | F 0.5M-0° F 0.5M-45° F 0.5M-90° |

A | 0 ... 0.5 mm | ± (0.5 μm + 0.75 %) | ø 3 mm | |||

| F1.5 | B / E | 0 ... 1.5 mm | ± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| F 1.5-90° | C | 0 ... 1.5 mm | ± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| F2 | B / E | 0 ... 2.0 mm | ± (1.5 μm + 0.75 %) | ø 10 mm | ||||

| F2.6 | B / E | 0 ... 2.6 mm | ± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| F 5 | B / E | 0 ... 5.0 mm | ± (1.5 μm + 0.75 %) | ø 10 mm | ||||

| F 15 | D | 0 ... 15 mm | ± (5.0 μm + 0.75 %) | ø 25 mm | ||||

| Eddy current sensors | N 0.3M-0° N 0.3M-45° N 0.3M-90° |

A | 0 ... 0.3 mm | ± (0.5 μm + 0.75 %) | ø 3 mm | |||

| N 0.7 | B / E | 0 ... 0.7 mm | ± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| N 0.7-90° | C | 0 ... 0.7 mm | ± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| N 2.5 | B / E | 0 ... 2.5 mm | ± (1.5 μm + 0.75 %) | ø 10 mm | ||||

| N 7 | D | 0 ... 7.0 mm | ± (5.0 μm + 0.75 %) | ø 20 mm | ||||

| Dual sensors | FN 1.5 | B / E | F: 0 ... 1.5 mm N: 0 ... 0.7 mm |

± (1.0 μm + 0.75 %) | ø 5 mm | |||

| FN 1.5-90° | C | F: 0 ... 1.5 mm N: 0 ... 0.7 mm |

± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| FN 2.6 | B / E | F: 0 ... 2.6 mm N: 0 ... 1.0 mm |

± (1.0 μm + 0.75 %) | ø 5 mm | ||||

| FN 5 | B / E | F: 0 ... 5.0 mm N: 0 ... 2.5 mm |

± (1.0 μm + 0.75 %) | ø 10 mm |

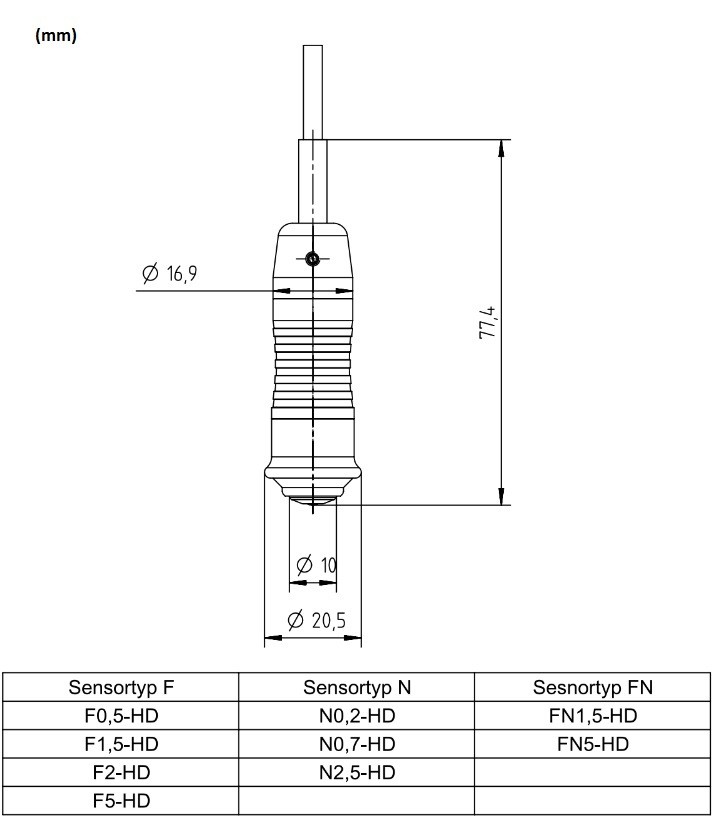

Dimensions

Complete Kit

The MiniTest 735 is supplied as a complete kit with:

- MiniTest 735 gauge

- SIDSP® sensor (according to choice)

- Calibration set with calibration standards and zero reference plate(s)

- Instruction manual in German, English, French and Spanish on CD

- 2 Mignon/ AA batteries

- Manufacturer’s Certificate

- MSoft 7 basic data transfer software

Accessories

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request