ESM303H Configurable Horizontal Tension and Compression Test Bench

The ESM303H Configurable Horizontal Tension and Compression Test Bench is no longer available and has been replaced by Series-F + EasyMesur F105 / F305 / F505 / F505H.

Click here to see the Series-F + EasyMesur F105 / F305 / F505 / F505H.

The ESM303H is a configurable horizontal test stand for tensile and compressive force measurements up to 1.5 kN. Its robust design make it perfectly suitable for applications in laboratory and production environments.

This horizontal test stand is also equipped with FollowMe ™ technology, which enables fine positioning of the crosshead and alignment of the test object by hand in order to move the display device or the measuring device to the desired position.Typical applications include rupture tests, cycle tests, load limit testing, constant force and elongation tests, tensile tests and compression tests. An easy-to-use menu enables simple configuration of the test speed, force and load limits as well as the setting of cycles, preload and many other functions. These settings can be protected by a password.

The ESM303H has memory for up to 50 profiles in order to be able to call up a series of test procedures. If the travel path of the ESM303H is not sufficient for an application, the travel path can be extended with a column extension. This modularity then also extends to the control functions.Individual functions such as travel measurement, cycles, constant force etc. can either be activated from the start or subsequently activated by using an activation code. This a-la-carte platform allows custom configuration to fit application needs as well as budget requirements.

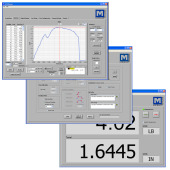

Force and displacement measurement data can be transferred directly to a PC with the the MESUR ™ gauge Plus software. The latter allows for graphical data evaluations and reports for data analysis to be created. Furthermore, there is the possibility of a complete control of the ESM303H test stand via the PC, by means of an individually written program that is supported by ASCII communication.

Features

- Selectable speed setting

- Right and left travel limit switches

- Adjustable, removable control panel may be mounted to the left or right end of the frame

- Password protection of test parameters

- Stepper motor-driven, producing smooth and quiet operation with no speed variation under load

- USB output of force or force vs. travel

- Compact footprint, suitable for crowded work benches

- Ergonomic design, with smart, clean cable management

- Integrated electronics assembly, easily removed and transported for service

- Adjustable mounting plate with T-slot base

| Function | Part No. | Description | Requirements |

|---|---|---|---|

| FollowMe | AF008 |

The crosshead reacts to pressure or tension exerted on the force gauge or load cell. The more pressure is applied, the faster the crosshead moves. This function is perfect for quick positioning, but also for fine adjustments. |

|

| Route display | AF009 |

The distance traveled is shown on the display of the control unit, as well as via USB output. An internal scale based on Renshaw technology enables a considerable improvement in accuracy compared to a traditional rotary encoder. |

|

| Computer control | AF010 |

The ESM300H and the connected force gauge can be completely controlled via a PC using a self-written program in an ASCII supported language. This option is not required to use the MESUR™gauge Plus software. |

|

| Programmable path limiters | AF011 |

The test stand stops or runs cycles between programmable maximum and minimum values. |

|

| Overload protection | AF012 | Protects a force gauge or force sensor from overloading by setting a desired percentage of the full scale value. The analog output voltage makes it possible to connect the test stand to almost any force measuring device with an analog output. |

|

| Automatic return | AF013 |

The crosshead moves up to a travel limiter, defined force value, programmed travel limit or a breakage detection, then stops and moves back at full speed to the opposite limit. |

|

| Cycle / rest time | AF014 |

Same function as the automatic rewind, but with the option of programming up to 100,000 cycles The dwell time for maximum and minimum values (are set independently) can be set to up to 10,000 seconds. |

|

| Independent upward and downward speed | AF016 | Individual adjustment of the upward and downward speed | - |

| Lower speed | AF017 | Extends the minimum speed range to 0.5 mm/min. | - |

| Higher speed | AF018 | Extends the maximum speed range up to 1,100 mm/min. | - |

| Breakage detection | AF019 |

The crosshead stops when the force suddenly drops. The value for this can be programmed as a percentage of the maximum force. |

|

| Holding the load | AF020 |

Moves the crosshead dynamically to hold a programmable load for an indefinite or definite time. |

|

| Preload / contact with the test object | AF021 |

Stops the crosshead and/or resets the displacement display to the original preload. Suitable for compression, elasticity, elongation tests and other applications. The preload can be set as a percentage of the maximum value of the load cell or force gauge. Three modes are available: (1) stop, (2) stop and reset and (3) reset without stopping. |

|

| Profiles | AF022 |

Offers the option of saving test parameters such as speed, travel limits, preloads, etc. Up to 50 profiles can be created. |

- |

| Complete Options Package | AFCOMP | Includes all options listed above including 09-1252 and 09-1158 cable. A Series 5 or 7 force gauge or indicator is required. | |

Specifications

| Load capacity: | 1.5 kN up to 24 in/min (610 mm/min) 1 kN >24 in/min (610 mm/min) |

| Maximum travel distance: | 457 mm |

| Speed range: | Standard: 13 - 330 mm/min Optional: 0.5 - 1,100 mm/min |

| Speed setting accuracy: | ±0.2% of setting |

| Speed variation with load: | ±0% (stepper motor driven) |

| Travel accuracy: | ±0.05 mm per 250 mm |

| Travel resolution: | 0.02 mm |

| Limit switch repeatability: | 0.03 mm |

| Power: | Universal input 80-240 VAC, 50/60 Hz |

| Weight: | 28,4 kg |

| Warranty: | 3 years (see individual statement for further details) |

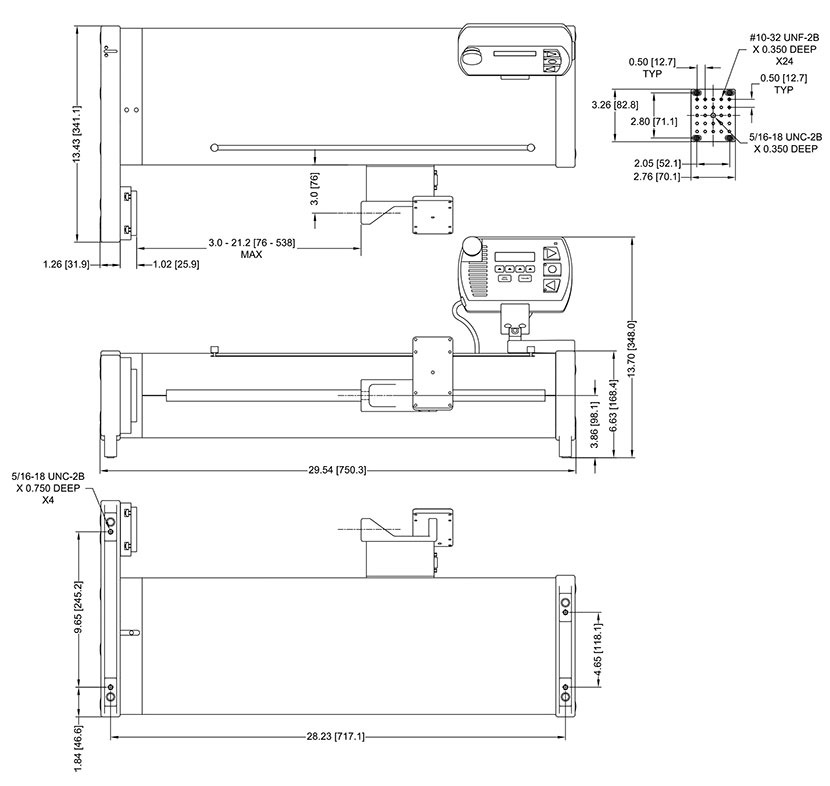

Dimensions

Complete Kit

The ESM303H test stand is delivered as shown, including the following accessories:

- 1 G1024 extension rod 2" (5.08 cm)

- 1 G1028 small hook

- 1 G1038 middle hook

- 1 G1039 coupling, No. 10-32F / F.

- 1 G1009 compression plate, 2" (5.08 cm) diameter

- 2 G1030 thread adapters, 5 / 16-18M to # 10-32F

- 1 G1067 thread adapter, 1 / 2-20 to # 10-32F

- 1 G1069 thread adapter, 5 / 16-18F to 1 / 4-28M

- 3 # 10-32 studs with hex nuts

- 4 knurled screw for display

- 2 knurled screw for limit switch

- 1 Allen key set

- 1 control panel

- 1 mounting bracket and control panel hardware

- 1 power cord

- 1 resource CD

Related Products

Series-5I Advanced Digital Force/Torque Indicator

- Interchangeable force and torque sensors through, separately sold, Plug & Test® technology

- High-speed 7.000 Hz sampling rate

- USB, RS-232, Mitutoyo, and analog outputs

More details

Series-7I Advanced Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 14.000 Hz sampling rate

- Continous data capture of up to 5.000 data points, at up to 14.000 Hz, downloadable to a PC

- 5 units of measurement, plus Coefficient of Friction and user-defined unit with configurable name

More details

ESM750 Tensile and compression test stand with large travel distance

- USB interface for data transfer to a computer

- Low-noise stepper motor works without speed change even under load

- Use with a force gauge or external load cell with display unit

More details

ESM303 Motorized Teststand with PC Control

- Selectable speed setting

- Stepper motor-driven, producing smooth and quiet operation with no speed variation under load

More details

ESM1500 Motorized Test Stand with high capacity

- Stepper is motor-driven, producing smooth and quiet operation with no speed variation under load

- Compatible with indicators and load cells, as well as force gauges

More details

MESURgauge Mesurgauge Load & Travel Analysis Software

- Sends data from a force or torque gauge and travel display to a PC for further analysis

More details