ESM750 Tensile and compression test stand with large travel distance

The ESM750 Tensile and compression test stand with large travel distance is no longer available and has been replaced by F755 / F1505.

Click here to see the F755 / F1505.

![]() The ESM750 provides you with all the benefits of our ESM range with the big plus of a longer travel distance up to 813 mm combined with a capacity of 3.4 kN.

The ESM750 provides you with all the benefits of our ESM range with the big plus of a longer travel distance up to 813 mm combined with a capacity of 3.4 kN.

This motorized test stand can be adapted to a variety of pressure and traction applications such as measurement tests of breaking, load capacity, extensibility, friction, pressure and tensile force. It is thus a very versatile and user friendly tensile and compressing test stand.

Its control panel is located on the side of the ESM750 test stand and an optional MESURgauge Plus software also enables controlling via a computer.

Furthermore, the ESM750 includes the FollowMe ™ function for a quick manual positioning of the probe, which is of considerable assistance when a large series of tests have to be done with a variety of sample sizes. Unauthorized or accidental modifications to the pre-saved settings can also be prevented through password protection.

This tensile and compressing test stand comes in 2 versions:

- LC version for use with an external load cell and force indicator

- FG version for deployment with a force gauge

A free MESUR ™ Gauge Lite data processing software is already included in the purchase price. Two additional softwares are available upon request to benefit from the full scope of features of this highly adaptable and easy to use tensile and compression testing motorized force stand.

Features

- USB interface for data transfer to a computer

- Low-noise stepper motor works without speed change even under load

- Use with a force gauge or external load cell with display unit

- Operation via the side-mounted operating panel

- Password protection for important settings

- Easily removable motor unit for maintenance

- CE mark

- 3 years warranty

Easy to use control unit

Easy to use control unit

The adjustable-angle control unit is comprised of a sturdy aluminum housing perfect for industrial production environments. The operation is facilitated by many optional additional functions such as the FollowMe function. Since the control unit is removable, it is also suitable for remote control or for table mounting with an optional mounting kit.

Travel limiters

Travel limiters

The measuring path can be adjusted by upper and lower travel limiters and thus stops the test bench with a repeatability of 0.025 mm.

Adjustable mounting plate for attaching handles & accessories

Adjustable mounting plate for attaching handles & accessories

The mounting plate can be repositioned for proper alignment on the X and Y axis. The mounting plate is provided with a matrix of threaded holes for mounting handles and accessories.

Modular construction

Modular construction

All the electronics are installed in a single panel, which is easy to remove for updates and maintenance.

Fo llowMe

llowMe

The FollowMe ™ feature allows you to manually control the force level. By applying pressure to the force transducer or force gauge, the crosshead positions itself at different rates of speed according to your applied pressure. Its high adaptability makes it suitable for quick positioning as well as for fine adjustments.

Force gauges

To take advantage of the full range of features of your dynamometer, you need a Series 5 or 7 Force Gauge, which is capable of both force versus time and force versus displacement measurements, and has a data interface.

Handles and pull-out handle adapter

Handles and pull-out handle adapter

A wide range of different holders, clamps and printing plates, etc. allows the test bench to be adapted to almost any test situation.

Indicator / measuring cell adapter

Indicator / measuring cell adapter

Allows you to mount a Series 5i or 7i display and mount a R01 or R03 force sensor.

MESUR data acquisition software

MESUR data acquisition software

Processes the data provided from the USB port of the ESM750, enabling tabular capture and visualization of data as well as statistics and reporting and output tools.

| Feature | Part. No. | Description | Requirements | |

|---|---|---|---|---|

| FollowMe | SF008 |

Crosshead movement responds to manually pushing or pulling on the force gauge shaft or load cell. Increasing force produces greater speeds. Ideal for setups and quick positioning. |

• Series 7 or 5 gauge or indicator |

|

| Travel indication | SF009 |

Travel is indicated on the control unit display, with out via USB. An internal scale utilizing Renishaw technology produces significantly higher accuracy than with conventional rotary encoder-base designs. Backlash and nonlinearity are virtually eliminated. |

• Series 7 or 5 gauge or indicator • Can not be added in field |

|

| Computer control | SF010 |

The ESM750 may be fully controlled by a PC through a custom-written program in any language supporting ASCII communications. Also responds to the legacy Chatillon TCD command set and legacy Nexygen TCD software (not available from Checkline Europe) |

• Series 7 or 5 gauge or indicator • SF009 Travel indication |

|

| Programmable travel limits | SF011 |

The stand stops at or cycles between programmable upper and lower travel distances |

• SF009 Travel indication | |

| Overload protection | SF012 | Protects a force sensor or force gauge against overload. Set the desired percentage of full scale of the gauge. Adjustable analoge output voltage setting allows the stand to interface with virtually any gauge with analog output. | • Series 7 or 5 gauge or indicator | |

| Auto return | SF013 |

The crosshead moves to a limit switch, force set point, travel position, or break, then stops and reverses direction at full speed to the other limit. Selectable reversing at force set point |

• Reversing at force set point: Series 7 or 5 gauge or indicator • Reversing at travel limit: SF011 programmable travel limits option • Reversing at break: SF019 break detection option |

|

| Cycling / dwell time | SF014 |

Same function as auto return but with the ability to program up to 100.000 cycles. Programmable dwell time for upper and lower limits (set independently) can be set up for up to 10.000 seconds. |

• Same as auto return, at the same speed in each direction. Add SF016 for independet up and down speeds | |

| Independent Up and Down speeds | SF016 | Individually configure speeds for the up and down directions | - | |

| Low speed extension | SF017 | Extends the standard speed range down to 0,02 mm/min. | - | |

| High speed extension | SF018-1 | Extends the max speed to 1,525 mm/min. | - | |

| Break detection | SF019 |

Crosshead stops at a programmable drop in force |

• Series 7 or 5 gauge or indicator | |

| Load holding | SF020 |

Dynamically adjusts the crosshead position to maintain a specified load for an indefinite or specified period of time. |

• Series 7 or 5 gauge or indicator • For a specified dwell time SF014 is required |

|

| Preload / sample touch | SF021 | Stops the corsshead and/or zeroes the travel display at an initial preload. Useful in tensile, compression, spring, elongation, and other applications. Preload is progammable as a percentage of force gauge/load cell full scale. Three modes: (1) stop, (2) stop and zero and (3) zero without stopping. | • Series 7 or 5 gauge or indicator | |

| Profiles | SF022 |

Save and recall sets of test parameters, such as speeds, travel limits, preload, etc. Maximum of 50 profiles may be stored. |

- | |

| Complete options package | SFCOMP | Includes all functions listed above. Requires a Series 7 or 5 gauge or indicator | ||

Related Products

Category Motorized Force Test Stands

Motorized Force Test Stands highly configurable for industrial or laboratory use. For various applications as break testing, cycling, limit testing & much more.

More details

ESM750S Single-Column Force Test Stand

- Ergonomic design, with smart, clean cable management

- Compatible with indicators and load cells, as well as force gauges

- Adjustable, removal controller with intuitive menu navigation

More details

ESM1500 Motorized Test Stand with high capacity

- Stepper is motor-driven, producing smooth and quiet operation with no speed variation under load

- Compatible with indicators and load cells, as well as force gauges

More details

Accessories

Series-5 Advanced Digital Force Gauge

- 3 Year Warranty

- ±0,1% accuracy

- High-speed 7.000 Hz peak sampling rate

More details

Series-7 Professional Digital Force Gauge

- High-speed sampling rate: 14.000 Hz

- Averaging mode - calculates average readings over time

- Continuous data capture of up to 5.000 data points, at up to 14.000 Hz, downloadable to a PC

More details

Model-5I Advanced Digital Force/Torque Indicator

- Interchangeable force and torque sensors through, separately sold, Plug & Test® technology

- Password protection for individual keys and calibration

- Sensor password protection, for preventing use of an unauthorized sensor

More details

Model-7i Advanced Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- Sensor password protection, for preventing use of an unauthorized sensor

- Password protection for individual keys and calibration

More details

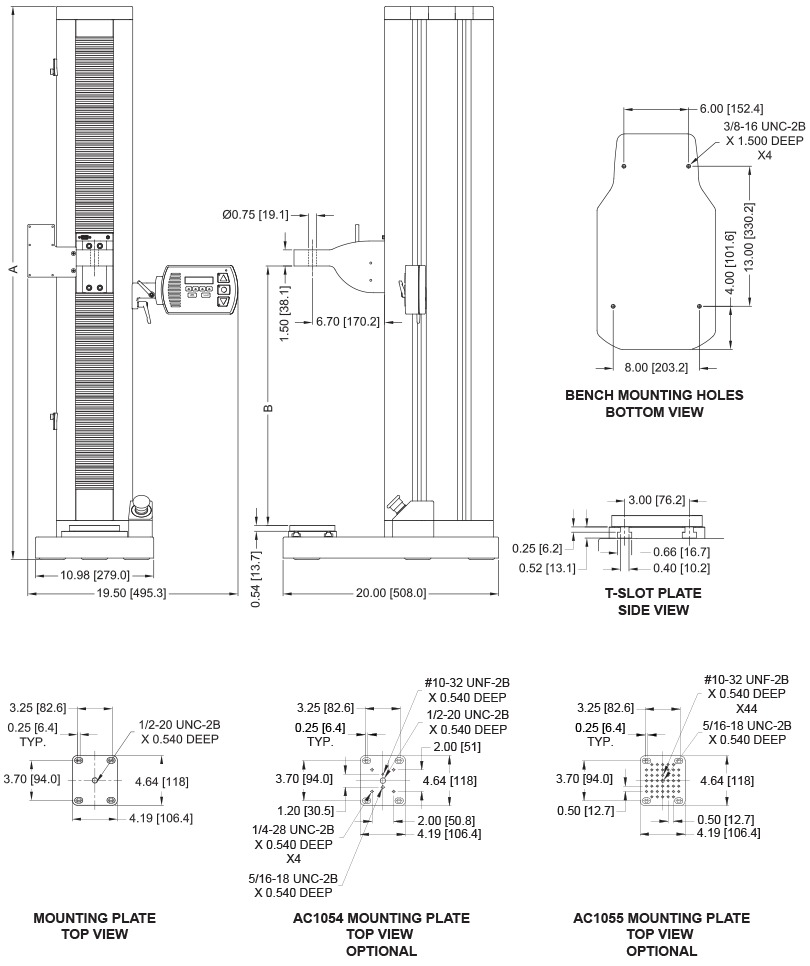

Dimensions

Complete Kit

The ESM 750 motorized teststand is supplied with the following accessories:

- AC1047-2 eye end kit

- G1088 spanner wrench (2x)

- Load cell / indicator mounting kit ( (ESM750LC, ESM750SLC)

- Force gauge mounting kit (ESM750FG, ESM750SFG)

- USB cable

- Interface cable, gauge/indicator to test stand

- Thumb screws for indicator / force gauge (4x)

- Allen wrench set

- Control panel

- Control panel mounting bracket with hardware

- Power cord

- Resource CD

Specifications

| Load capacity: | 3,4 kN at < 900 mm/min // 2,3 kN at > 900 mm/min |

| Maximum travel distance: | 813 mm |

| Standard speed range: | 10 - 600 mm/min |

| Available speed range: | 0.02 - 1,525 mm/min |

| Speed setting accuracy: | ±0.2% of setting |

| Speed variation with load: | ±0% (stepper motor driven) |

| Travel accuracy*: | ±0.05 mm per 250 mm / * Because load cell deflection and system deflection are present and not automatically compensated for, this equipment is recommended for applications requiring at least 5 mm of travel distance. |

| Travel resolution: | 0.02 mm |

| Limit switch repeatability: | ±0.03 mm |

| Power: | Universal input 80-240 VAC, 50/60 Hz, 120 W |

| Weight: | 84 kg |

| Shipping weight: | 107 kg |

| Warranty: | 3 years |

| Conformity: | CE |